Their efficiency drops to 90 percent after only 600 hours? Isn’t that actually awful?

I suppose it depends on whether the degradation is linear or if it plateaus after the initial decrease.

So, how does that compare to silicon panels? And maybe it is worth it if they are easier, cheaper or more environmentally friendly to produce?

silicon panels drop at 1 percent a year

I think that’s the big idea with perovskites. You can potentially make them with basic chemistry instead of vacuums and furnaces like silicon panels. It’s a bit of a pipe dream at this point to have ones that are comparable to silicon in long-term performance, but if you can print them like newspaper maybe that doesn’t matter.

I’m curious about their efficiency drop off if that’s what happens after 25 days.

Agreed. Will they keep 90% for the next 10 years, or will the efficiency drop by 10% every 25 days?

I’d say “disposables” even in the latter case, but the best ones right now use lead.

Yup, that’s terrible. PSC’s still have a long way to go and we need to find encapsulation technologies to extend their life more, but where they shine is that they should be dirt cheap. If they cost 1/4 of silicon based cells, but only last 1/2 as long, that’s still a massive improvement.

Wouldn’t the energy used for manufacturing, shipping, gathering, and recycling twice as many solar panels outweigh the benefits? That’s a lot of extra logistics to deal with

In theory, the cost of energy used in manufacturing and logistics is covered by the purchase price.

Also there’s lead in perovskite! This stuff is sounding better by the minute.

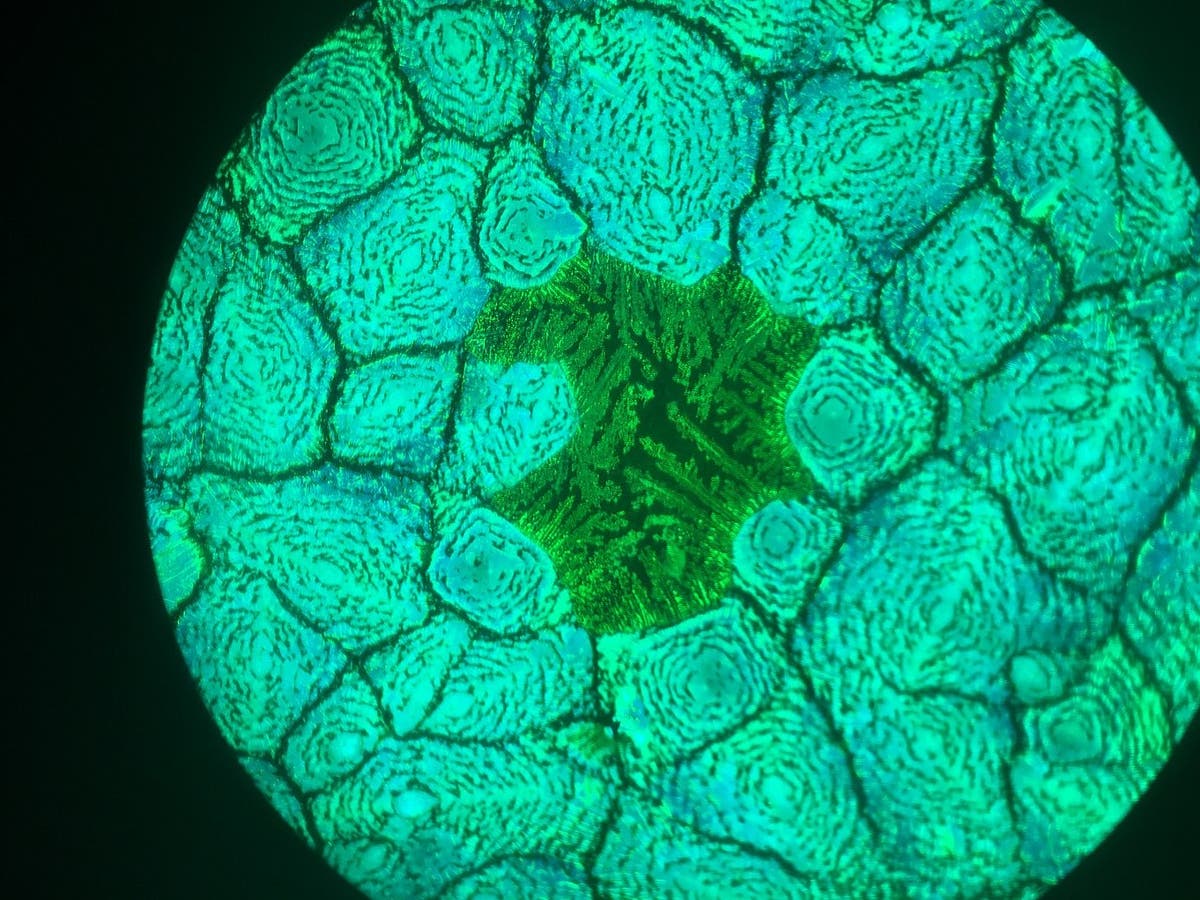

I feel like I should clarify because the article didn’t do a good job at explaining: perovskite is a kind of structure, not a particular material. They have the generic formula ABX3 (where A and B are different kinds of cations and X is some kind of anion), although not everything with the formula is a perovskite.

Simple perovskites include some lead-containing materials like lead titanate, but also lead-free materials like barium or strontium titanate. And in general there are a lot of different kinds of perovskites, especially because some of the structural sites can be filled by small organic molecules instead of pure elements.

Edit: I think I was misreading the journal article before my edit (it’s early I’m not awake yet lol). I had said it looks like they’re using a lead-based perovskite but actually I can’t tell what exactly they’re using with a quick skim. The article is very review-y, the formula I thought they were using is from another paper. I’ll have a more thorough look later.

Edit 2: It’s a review paper, and the way it was described in the linked news article is kinda misleading. Its not specifically about this company’s particular composition or architecture.

I’m confused as hell. This looks like just a general review of perovskite solar cells. Where in there is the direct connection to this particular product?

Yeah as far as I can tell without a close read of the paper – which I just don’t have time to do – it’s a review paper that just happens to have been written by some of the people involved in this commercial endeavor. (I imagine they don’t want to share their proprietary composition and architecture.) It seems like the reporter covering this didn’t catch the distinction.

To my previous comment, this means we really have no idea if they’re using a lead-containing composition or not. Like I mentioned, perovskites are a large class of materials. Since the review paper has a section on the challenges around lead containing compositions I’d hope they’re not using lead, but who knows 🤷♂️

Ah, okay.

If that figure is true then yes that seems awful. It stopped me to look into it and at least according to Wikipedia ”In July 2015, major hurdles were that the largest perovskite solar cell was only the size of a fingernail and that they degraded quickly in moist environments.However, researchers from EPFL published in June 2017, a work successfully demonstrating large scale perovskite solar modules with no observed degradation over one year (short circuit conditions). Now, together with other organizations, the research team aims to develop a fully printable perovskite solar cell with 22% efficiency and with 90% of performance after ageing tests.”

So maybe these particular cells aren’t great, but there is hope that it’s not an intrinsic unsolvable issue.

Adding from communist’s comment, if they don’t stay efficient very long, how easy are them to recycle? Apparently they use common materials, but does that necessarily means it’s common to recycle?

It’s a metal salt, basically. The best ones according to the review cited use lead and halides, with formamidinium, methylammonium or Cesium. So, pretty easy to recycle, you could turn it back into the original ingredients with basic electroplating.

They’re okay for niche applications, but the use case is pretty narrow: situations where you want high efficiency solar harvesting, but only for a limited period (because the material degrades). Oh, and you can’t use them for (say) cheap solar powered kids’ trinkets, because they contain lead.